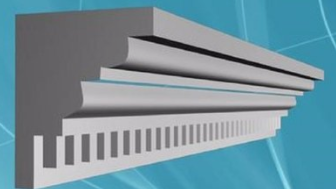

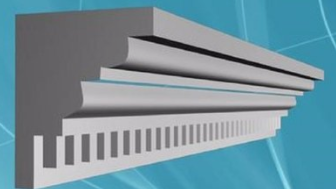

What are the installation procedures and requirements of shared components? During the construction of building decoration, GRC component is a new type of building material. As a new type of exterior wall decoration material, GRC component is widely used because of its advantages of small amount, high strength, good freeze-thaw resistance, strong plasticity, and rich and diverse decoration shapes, So today we will give you the installation process of GRC components, the installation requirements of GRC components and the precautions for GRC component installation: Hainan GRC component

Installation process of grc components

1、 Installation process of GRC components:

1. Recheck the site size 2. Positioning and setting out (snapping, hanging and hanging) 3. GRC component assembly treatment (cutting and polishing) 4. Positioning and drilling installation of GRC embedded parts on the wall, component installation 5. Installation node concealment 6. Joint closing treatment 7. Waterproofing treatment 8. GRC component surface treatment.

Second, installation requirements of GRC components:

1. Before the installation of components, the surface of the building connection structure shall be treated to ensure its flatness and firmness.

The installation of components shall be horizontal, vertical, overall line, complete decoration assembly, smooth and smooth curve, and the surface of components shall be free of pollution and defects.

2. If there are defects such as missing edges and corners on the surface of the component, cement mixing materials shall be used for repair after installation.

3. Before installation, the elevation line, horizontal, vertical and component center control line shall be snapped on the external wall according to the construction drawings to control the installation of GRC components on the same horizontal line.

4. The installation characteristics and overhanging size of GRC lines shall be fully considered when erecting the external frame to ensure that there is sufficient spacing when installing GRC lines

5. The installation error of components shall meet the following requirements:; (1) The perpendicularity error of unit decorative surface is ≤ 5mm/floor height, and the total error is ≤ 50mm;

(2) Straightness error of unit decorative surface ≤ 5mm/2m, and total error ≤ 50mm;

6. The installation joint shall be smooth, and if the error exceeds 5mm, it shall be polished. 7. Gaps shall be reserved for the connection of components and shall be treated according to the design requirements.

8. The parts with waterproof requirements shall be treated with waterproof treatment, and necessary anti freezing measures shall be taken. Links and welds exposed to the air shall be subject to reliable anti-corrosion treatment. Hainan GRC component

9. Fixing method of rear anchor connection point:

(1) The connecting structure of the building is cast-in-place concrete structure, the actual strength level is greater than C20, the thickness is greater than 1.5 hef (hef means the effective anchoring depth should not be less than 50 mm), and when it is greater than 100 mm, the anchor bolt or expansion bolt with a diameter of not less than 8 mm should be used. If it does not meet the above requirements, it should be installed by welding connection.

(2) The connecting structure of the building is a hollow block masonry structure. The masonry strength is greater than Mu7.5, the mortar strength is greater than M5, and the masonry thickness is greater than or equal to 370 mm. The replacement block shall be poured with C20 grade or above expanded fine aggregate concrete, with a thickness of 240 mm and a height and width of not less than 240 mm. The anchor bolt shall be installed in the center of the replacement block, which does not meet one of the above requirements, Welding connection shall be adopted for installation.

10. Installation of link points between components and buildings:

Installation of villa GRC components

Third, the installation of GRC components must pay attention to

First of all, the GRC installation should be carried out after the completion of the building facade scraping. If you are careful to use the surface decorative materials to cover the gap during the installation of GRC materials before painting the surface. In addition, it should be noted that many GRC trims need to be grouted after installation to ensure that the bonding between GRC and the main structure is firm. In this way, GRC buildings can have a relatively long service life.

After installation of GRC materials and grouting, the surface course can be brushed to avoid cracks due to different linear expansion coefficients of GRC and wall materials. GRC shall be applied to the exterior wall when painting the exterior wall. We must pay attention to the problems mentioned here during construction.

That's all for sharing the installation process and requirements of GRC components. GRC components are characterized by high strength, high toughness, long service life, large plastic shape, and simple fabrication and installation, so they are widely used in villas and buildings. Hainan GRC component