The rapid development of urban sculpture has increasingly become an important part of environmental art and the expression of urban image. Sculpture materials are mostly natural stone, artificial stone, wood, metal, cement and new materials such as plastic, rubber, stainless steel, aluminum alloy, gold copper, glass fiber reinforced plastic, etc. In order to cater to the trend of people's "returning to nature", break through the stereotype of traditional sculpture "steel and cement", enrich the environmental space, better protect and beautify the environment, reflect the meaning of sculpture, and make the urban landscape more attractive and cultural and artistic taste, "green sculpture" came into being at the historic moment, quietly sweeping all countries in the world. It refers to the artistic image with different postures and vivid charm, which is carefully cultivated and pruned by various green plants, especially trees. It combines garden and sculpture art, skillfully integrates the theme of "people, animals and nature" into beautifying the urban environment, and has a wonderful effect of shaping a beautiful image of the city and protecting the urban environment. The green sculptures are generally novel in design and rich in meaning. The overall style is beautiful and grand, full of modern flavor. Green sculptures are not only rich in materials, but also can release oxygen needed by human beings, absorb carbon dioxide, purify air, regulate air humidity, and bring health and artistic enjoyment to the city.

The openwork carving technique is an original carving technique in Putian. There are still many "gold inlaid openwork lanterns" and "embossed flower windows" in the Palace Museum in Beijing, which all support the traditional craft charm of Putian wood carving. From the end of the Ming Dynasty to the beginning of the Qing Dynasty to the Republic of China, Putian wood carvings were mostly made of longan wood, which was rich in local production. Hangzhou EPS components Carved into various military generals, women or gods, antiques, supplemented by high quality EPS components The painting with old lacquer makes the work more deep in color. Zhu Bangshou, Huang Dangui, Chen Xiange and other famous painters, together with Liu Ronglin, formed a round sculpture character style characterized by Pu style military generals. So far, many figures and architectural decoration wood carvings have been left for future generations in Guandi Temple, Yuanxia Village, Jiangkou Town, Jiufeng Village, Wutang Town and other old folk houses, These masterpieces, which combine round, transparent and relief carvings, are treasures of Putian wood carving art.

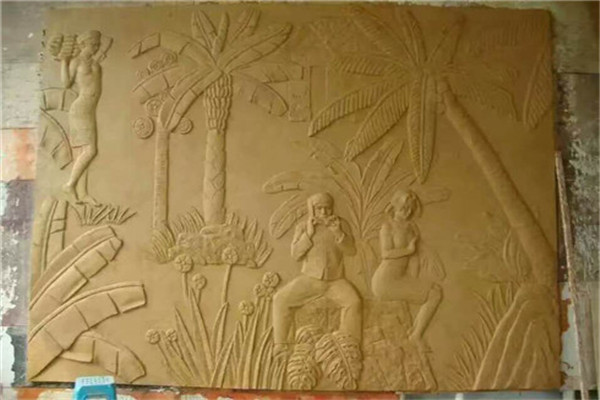

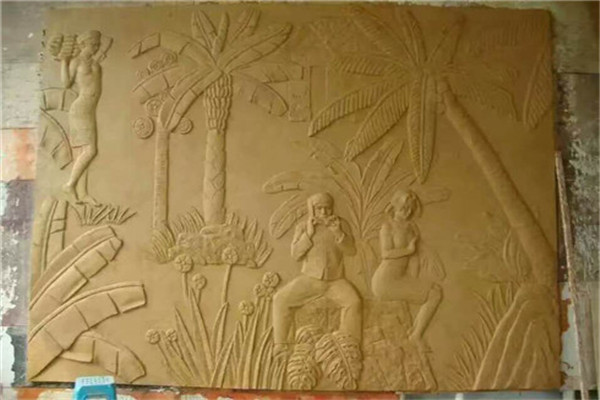

Marble, granite, Hui'an stone, Qingtian stone, Shoushan stone, Guicui stone and other materials are generally used for stone carving. Granite and marble are suitable for carving large statues; Qingtian stone and Shoushan stone are rich in color, which are more suitable for small stone carvings. There are many ways to make stone carvings. According to the nature of stone materials and the habits of the carvers, stone carvings can be roughly divided into two types: first, traditional methods. Conception, composition, modeling and stone carving are all done by individuals alone. For large-scale carving of lines, the horizontal and vertical lines shall be drawn on the stone, the grid shall be made to take materials, and the simple measurement and positioning method shall be used for carving. The second is to adopt a new process, that is, first make a clay sculpture, turn it into a plaster statue, then take the plaster statue (model) as the basis, rely on the point shaped instrument, and then carve it into a stone statue.

Copper casting is an important part of Chinese traditional culture and art. Copper casting has a long history and mature technology. The process of casting copper is more complicated than that of forging copper, and the artistic creation has a good recovery. Therefore, it is suitable for becoming the material of fine works and is very popular with artists, especially figure sculpture. But it is easy to oxidize, so pay more attention to maintenance. Each cast copper artwork is made through 11 complex and rigorous processes, which include traces of traditional handicrafts, lines and modern technology of precision casting. Cast copper is put into the sintering furnace and sintered at 1000 ℃ - 1150 ℃ according to different metal materials. The copper liquid is immediately cast into the ceramic shell. After cooling, the outer ceramic shell is broken, and the copper product rough embryo is peeled out.