Full name of GRC component: GRC building detail decoration component. Abbreviation of the specification: GRC building details. Because the name of GRC building detail decoration component is too long to remember, lines are often referred to as GRC components. Because of the prevalence of European customs in recent years, they are also often called GRC European components, GRC Roman columns, GRC eaves lines, GRC decorative lines, GRC corner lines, GRC door and window covers, GRC vase railings, etc. According to the national standard Code for Acceptance of Construction Quality of Building Decoration Engineering (GB50210-2001) issued by the Ministry of Construction, GRC building detail decoration component belongs to one of the building components in the detail project of building decoration engineering. The product is to mix the raw materials according to a certain proportion, and Hainan sculpture is poured into the mold, which can produce products with rich shapes and diverse textures. According to the different needs of customers and designers, we can carry out arbitrary art modeling to perfectly realize the designer's design dream.

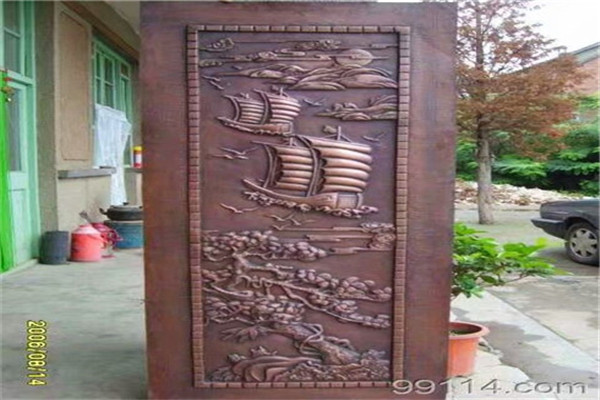

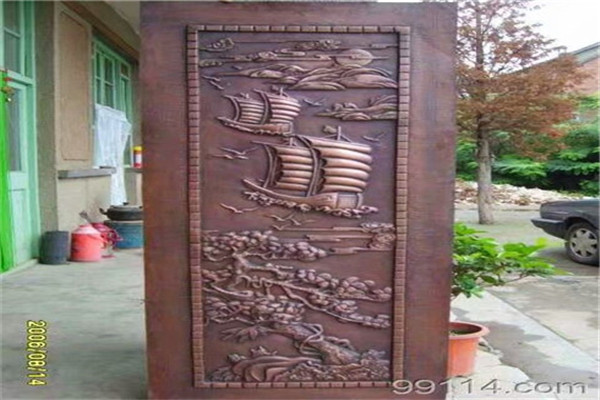

Copper casting is an important part of Chinese traditional culture and art. Copper casting has a long history and mature technology. The process of casting copper is more complicated than that of forging copper, and the artistic creation has a good recovery. Therefore, it is suitable for becoming the material of fine works and is very popular with artists, especially figure sculpture. But it is easy to oxidize, so pay more attention to maintenance. Each cast copper artwork is made through 11 complex and rigorous processes, which include traces of traditional handicrafts, lines and modern technology of precision casting. Cast copper is put into the sintering furnace and sintered at 1000 ℃ - 1150 ℃ according to different metal materials. The copper liquid is immediately cast into the ceramic shell. After cooling, the outer ceramic shell is broken, and the copper product rough embryo is peeled out.

Jade carving, commonly known as jade ware, has a long history. Jade pendants appeared in China during the Neolithic Period, and the jade carving skills of the Shang Dynasty were relatively mature. There are dozens of jade carving materials, such as white jade, jasper, sapphire, black jade, jadeite, crystal, agate, topaz, single jade, Xiuyu, etc. Because the jade itself is fine, hard and warm, or white as cream, or green and green, bright and lovely color, suitable for making valuable decorations. As for the production of jade, most people think it is carved with a carving knife, but it is not. The jade is hard, and the carving knife cannot cut it into it. Instead, it is polished by various shapes of drill bits, emery and water, depending on the shape of the work. Therefore, it takes a long time to complete a jade carving.

Shallow relief has a low rise, a large compression of shape, a strong sense of plane, and is closer to the form of painting to a greater extent. It does not rely mainly on physical space to create space effects, but uses more painting techniques or perspective, illusion and other processing methods to create more abstract compression space, which is conducive to strengthening the dependency of relief suitable for the carrier. The ancient Assyrians in Mesopotamia were probably the best at using this method cost performance EPS line An artist of artistic expression. In a series of "Assyrian Hunting Pictures", they used the technique of bas relief very well to express the lively artistic image with a sense of rhythm and rhythm, and to show the inner feelings of the characters and animals with complex dynamics. EPS line manufactor The selection of the compression degree of relief space usually takes into account the function, theme, environmental location, light and other factors of the performance object, of which the environment and light factors play a decisive role. Excellent sculptors can always handle these relationships well, so that the works can achieve good visual effects.

Exterior wall decorative panel is a new type of integrated material for building exterior wall decoration and insulation developed in recent years, which is composed of polyester baking paint or fluorocarbon paint, carved aluminum zinc alloy steel plate, polyurethane insulation layer and glass fiber cloth; It is mainly used for exterior wall decoration and energy-saving reconstruction of gymnasiums, libraries, school and hospital office buildings, villas and other buildings; The main functions are building decoration, heat preservation, energy conservation, heat insulation, sound insulation, waterproof and mildew proof. The metal surface decorative insulation board is a large format external wall board produced in industrialization. It has good durability and low maintenance cost due to dry installation construction. It integrates the external wall insulation and decoration functions, conforms to the development direction of building energy conservation "modularization" technology, and is an advanced technology vigorously promoted in the field of external temperature protection technology of building walls in China.