First of all, make the structural layer of the steel bar mountain mesh on the stone wall. According to the Hainan sculpture stone structure, the density of the steel bar is about 30 to 50 cm. Then, bind and weld the steel bar on the exposed steel bar head. Pay attention to the need to shape the approximate shape. After the steel bar is welded, tie a layer of steel wire mesh outside, and then start painting. The first painting is to make a base. For the second painting and shaping, it is necessary to make some rock texture, such as concave and convex, wrinkles, because the above steps must be grasped, and craftsmen must make the surface very artistic! Must have basic skills of modeling and stone molding. It is effective to spray stone like paint. Before large-area spraying, small samples were tested to show speckled particles in natural stone. Fill the gaps in the stone wall with earth and then plant them. Maybe fill some ceramic bottles and jars that are harmonious with the theme materials. There are still some water sources in the pottery to supplement its spatial diversity. There is also a new type of plastic stone, which is made of light materials such as environment-friendly building raw materials, fine resins, efficient reinforcing agents, pro aggregate, imported pigments, etc., by mixing, processing, molding, and then steaming at high temperature. Each product has different shapes and various combinations, which are no different from real stones in texture, color and texture.

Stone carvings pay attention to lifelike shapes, round and delicate techniques, and smooth and free patterns. Its traditional skills began in the Han Dynasty, matured in the Wei and Jin Dynasties, and became popular in the Tang Dynasty. There are mainly garden sculptures, architectural sculptures, sculptures, stone carving handicrafts, and hundreds of products: marble mantelpiece, figure sculptures, reliefs, abstract sculptures, fountains, flower pots, Roman columns, railings, pavilions, busts, door covers, stone benches, bathtubs, animal carvings, tombstones, antique sculptures, etc. Stone carvings have a long history. They pay attention to lifelike shapes, round and delicate techniques, and smooth and free patterns. Carving products mainly include figures, animals, fireplaces, flower pots, balustrades, fountains, reliefs, dragon pavilions, dragon pillars, jade pavilions, birds and animals, and various high-quality sculptures. It not only has the charm of ancient art, but also has the elegant and fast modern art style. It enjoys the reputation of "excellent workmanship" and "groundbreaking" at home and abroad. It is a collection of creative, design, production of various works of art. In short, it is a work of art carved from stone.

Jade carving, commonly known as jade ware, has a long history. Jade pendants appeared in China during the Neolithic Period, and the jade carving skills of the Shang Dynasty were relatively mature. There are dozens of jade carving materials, such as white jade, jasper, sapphire, black jade, jadeite, crystal, agate, topaz, single jade, Xiuyu, etc. Because the jade itself is fine, hard and warm, or white as cream, or green and green, bright and lovely color, suitable for making valuable decorations. As for the production of jade, most people think it is carved with a carving knife, but it is not. The jade is hard, and the carving knife cannot cut it into it. Instead, it is polished by various shapes of drill bits, emery and water, depending on the shape of the work. Therefore, it takes a long time to complete a jade carving.

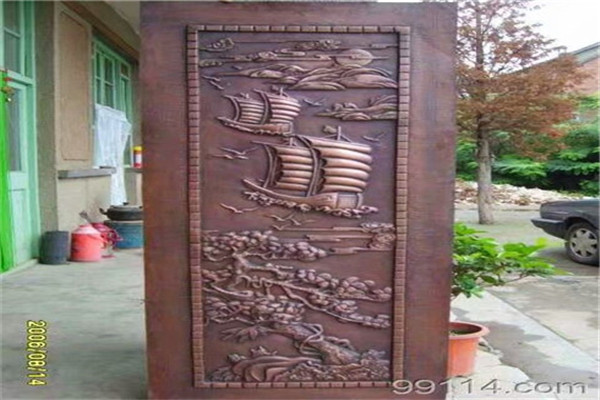

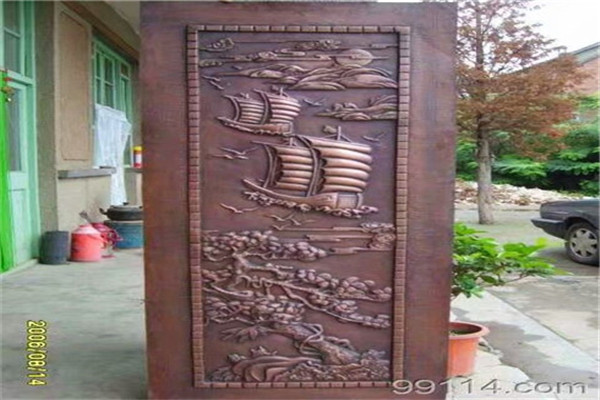

Copper casting is an important part of Chinese traditional culture and art. ascend a height EPS components Copper casting has a long history and mature technology. The process of casting copper is more complicated than that of forging copper, and the artistic creation has a good recovery. Therefore, it is suitable for becoming the material of fine works and is very popular with artists, especially figure sculpture. But it is easy to oxidize, so pay more attention to maintenance. Each cast copper artwork is made through 11 complex and rigorous processes, which have traces of traditional handicrafts, recommend EPS components The lines also have the modern technology of precision casting. Cast copper is put into the sintering furnace and sintered at 1000 ℃ - 1150 ℃ according to different metal materials. The copper liquid is immediately cast into the ceramic shell. After cooling, the outer ceramic shell is broken, and the copper product rough embryo is peeled out.

EPS components have high strength, excellent water resistance and good toughness. Simple construction is an important advantage of this product. During construction, no embedded parts or riveting parts are required. The special bonding mortar provided by our company can be directly bonded to the wall base. This kind of mortar has high bonding strength, and slightly larger components will not fall off even when people walk on it after being pasted on the wall base. Easy installation. Using special bonding materials and methods, one person can install and construct, especially for large components, only bonding installation is required. Hainan sculpture decorative line (component) is smooth and beautiful, and there is no gap between the lines. Because the gap repair material is used between the two lines, the gap disappears completely. There will be no cracks in future use. Completely solved the problem of external thermal insulation of cold and hot bridges, allowing designers and builders to give full play.