EPS decorative components are mainly used for door jambs, window jambs, cornice lines, waist lines, court columns and other parts of villas, European style residential quarters, hotels and commercial streets. It was first widely used in Europe, America and other countries in the 1980s, and it is an epoch-making upgrade product of traditional components. EPS components are made of high-strength flame-retardant polystyrene as the matrix, alkali resistant glass fiber mesh cloth as the middle layer, and the outer layer is compounded by inorganic anti-aging polymer emulsion. The product is light and impact resistant. High strength, excellent water resistance, good toughness. EPS decorative line can prevent fire without emitting toxic substances, and is an environmentally friendly high-quality product. Multiple varieties and models (such as lines, Roman columns, insulation boards, decorative pieces, etc.) can be installed on the four sides of windows, door edges, hall wrapped columns, cornice lines and wall bodies; It can also be sprayed with personalized paint color on the surface, and can also be made into a cultural effect of imitation stone, making the facade of the building more beautiful, and bringing new and different ideas to architectural designers.

Exterior wall insulation decorative board is also called exterior wall insulation board, exterior wall board, metal curtain wall board, etc. It is a kind of exterior wall thermal insulation decorative wallboard made of high-quality galvanized sheet with color coating printing and thermal insulation materials. It is also a kind of new exterior wall external insulation board, which changes the disadvantages of single decoration color and no insulation layer in the past. The external thermal insulation system of thermal insulation decorative plate is a kind of external thermal insulation technology that has developed very rapidly in recent years. It has the advantages of factory prefabrication site quality control, cycle saving, and very beautiful curtain wall effect. Now, more and more public buildings and high-grade residential buildings are using the external thermal insulation technology of thermal insulation decorative panels. Various regions are also constantly issuing standards and guidance documents for the thermal insulation decorative board system, which is good news for the development of thermal insulation decorative board products.

The handicrafts made by forging copper are lifelike in shape and easy to sculpt Shanghai Sculpture processing The lines of the handicrafts are very smooth. Even if you look carefully, you will not find any shortcomings. Of course, you need to ensure the craftsmanship of the sculptors. Only the craftsmanship can ensure the shape and image of the forged copper sculpture handicrafts. In the process of production, brass or copper plate is usually used as the base, and then forging is carried out, and multiple forged copper plates are used to show the overall image of the handicraft. For many sculpture artists, corresponding copper plates are selected for forging. Sculpture processing manufactor The forging copper processing technique is unique. Attention should be paid to heating the copper plate, then forging, after a certain forging, polishing and polishing to make the surface smooth, so as to become the desired forging copper sculpture handicrafts, which are all hand-made, very public welfare, natural and vivid in appearance. Attention should be paid to the handicrafts produced, Certain maintenance is required to ensure its appearance is not affected.

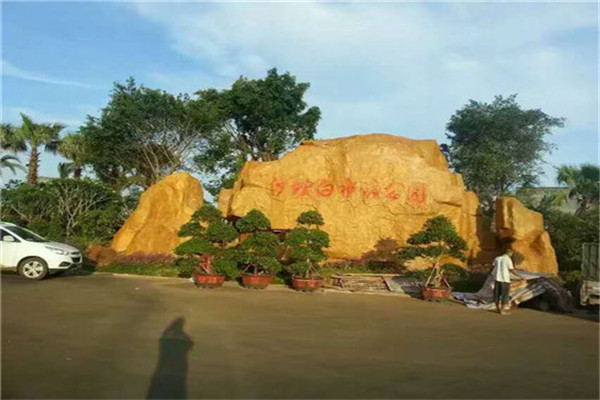

First of all, make the structural layer of the steel bar mountain mesh on the stone wall. According to the Hainan sculpture stone structure, the density of the steel bar is about 30 to 50 cm. Then, bind and weld the steel bar on the exposed steel bar head. Pay attention to the need to shape the approximate shape. After the steel bar is welded, tie a layer of steel wire mesh outside, and then start painting. The first painting is to make a base layer. For the second painting and shaping, it is necessary to make some rock texture, such as concave and convex, wrinkles, because the above steps must be grasped, and craftsmen must make the surface very artistic! Must have basic skills of modeling and stone molding. It is effective to spray stone like paint. Before large-area spraying, small samples were tested to show speckled particles in natural stone. Fill the gaps in the stone wall with earth and then plant them. Maybe fill some ceramic bottles and jars that are harmonious with the theme materials. There are still some water sources in the pottery to supplement its spatial diversity. There is also a new type of plastic stone, which is made of light materials such as environment-friendly building raw materials, fine resins, efficient reinforcing agents, pro aggregate, imported pigments, etc., by mixing, processing, molding, and then steaming at high temperature. Each product has different shapes and various combinations, which are no different from real stones in texture, color and texture.