Exterior wall insulation decorative board is also called exterior wall insulation board, exterior wall board, metal curtain wall board, etc. It is a kind of exterior wall thermal insulation decorative wallboard made of high-quality galvanized sheet with color coating printing and thermal insulation materials. It is also a kind of new exterior wall external insulation board, which changes the disadvantages of single decoration color and no insulation layer in the past. The external thermal insulation system of thermal insulation decorative plate is a kind of external thermal insulation technology that has developed very rapidly in recent years. It has the advantages of factory prefabrication site quality control, cycle saving, and very beautiful curtain wall effect. Now, more and more public buildings and high-grade residential buildings are using the external thermal insulation technology of thermal insulation decorative panels. Various regions are also constantly issuing standards and guidance documents for the thermal insulation decorative board system, which is good news for the development of thermal insulation decorative board products.

Lacquer carving is a traditional handicraft in China, also called red carving. Its technique began in the Tang Dynasty, and its process is extremely complex. Paint, tire The process of polishing and polishing is complicated and takes a long time, so large lacquer carvings are also extremely expensive and have always been the furnishings of royal families and nobles in ancient times. Lacquer carving is a technique to carve patterns on stacked flat lacquer bodies. It was introduced into Beijing during the Yuan and Ming Dynasties. Through the painstaking research of lacquer carving artists, the lacquer carving technique has gradually become perfect and mature, and lacquerware has become a handicraft with Beijing characteristics. Beijing lacquer carving is as famous as Hunan Hunan embroidery and Jiangxi Jingdezhen porcelain. It has been known as the "Three Masters of Chinese Arts and Crafts". For many years, lacquer carving has been favored by lacquer carving art lovers at home and abroad for its unique craft, exquisite and beautiful shape without losing a sense of solemnity.

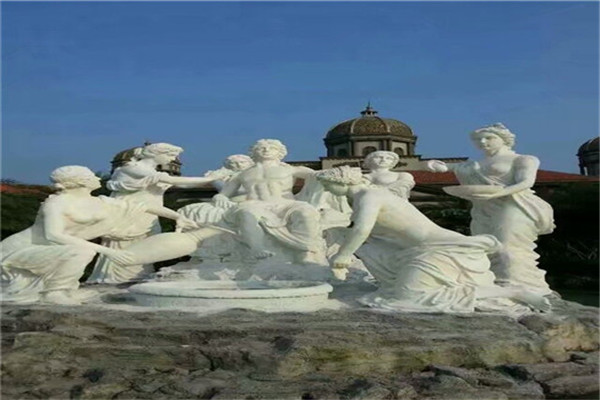

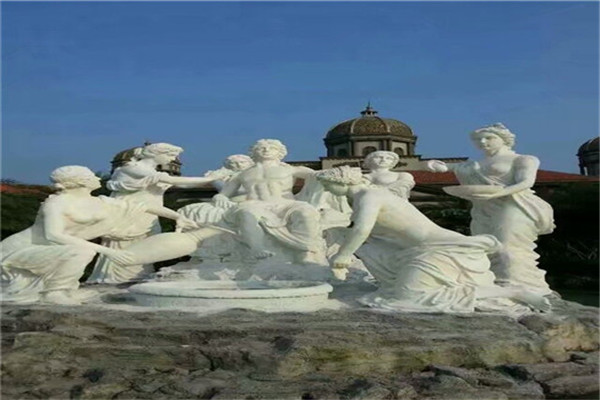

Shallow relief has a low rise, a large compression of shape, a strong sense of plane, and is closer to the form of painting to a greater extent. It does not rely mainly on physical space to create space effects, but uses more painting techniques or perspective, illusion and other processing methods to create more abstract compression space, which is conducive to strengthening the dependency of relief suitable for the carrier. The ancient Assyrians of Mesopotamia were probably the artists who were best at performing art by this means. In a series of "Assyrian Hunting Pictures", they used the technique of bas relief very well to express the lively artistic image with a sense of rhythm and rhythm, and to show the inner feelings of the characters and animals with complex dynamics. The selection of the compression degree of relief space usually takes into account the function, theme, environmental location, light and other factors of the performance object, of which the environment and light factors play a decisive role. Excellent sculptors can always handle these relationships well, so that the works can achieve good visual effects.

The handicrafts made by forging copper are lifelike in shape, easy to sculpt, and the lines of the handicrafts are very smooth. Even if you look carefully, you will not find any shortcomings. Of course, you need to ensure the craftsmanship of the sculptors. Only the craftsmanship can ensure the shape image of the forged copper sculpture handicrafts. In the process of production, brass or copper plate is usually used as the base, and then forging is carried out, and multiple forged copper plates are used to show the overall image of the handicraft. For many sculpture artists, corresponding copper plates are selected for forging. The forging copper processing technique is unique. Attention should be paid to heating the copper plate, then forging, after a certain forging, polishing and polishing to make the surface smooth, so as to become the desired forging copper sculpture handicrafts, which are all hand-made, very public welfare, natural and vivid in appearance. Attention should be paid to the handicrafts produced, Certain maintenance is required to ensure its appearance is not affected.

The dough figurines are commonly known as dough figurines, gift buns, flower cakes and dough figurines. It uses glutinous rice flour as the main material, mixed into different colors, and shapes various vivid images with hands and simple tools. In the old society, the dough figuring artists "just make a living and walk around in tears", carrying suitcases, walking around villages and towns, and working in the streets, are deeply loved by the masses. However, their works are regarded as a gadget and cannot be put on the stage of elegance. Today, dough sculpture art is valued as a precious intangible cultural heritage, and gadgets have also entered the art palace. The dough kneader takes materials at will according to his needs. After several times of kneading, rubbing, rubbing, and lifting, he uses a small bamboo knife to skillfully place, cut, carve, scratch, shape his body, hands, and head, and put on hair ornaments and clothes. In a moment, the vivid artistic image will be released.

Copper casting is an important part of Chinese traditional culture and art. Hefei EPS decorative materials Copper casting has a long history and mature technology. The process of casting copper is more complicated than that of forging copper, and the artistic creation has a good recovery. Therefore, it is suitable for becoming the material of fine works and is very popular with artists, especially figure sculpture. But it is easy to oxidize, so pay more attention to maintenance. Each cast copper artwork is made through 11 complex and rigorous processes, which have traces of traditional handicrafts, recommend EPS decorative materials The lines also have the modern technology of precision casting. Cast copper is put into the sintering furnace and sintered at 1000 ℃ - 1150 ℃ according to different metal materials. The copper liquid is immediately cast into the ceramic shell. After cooling, the outer ceramic shell is broken, and the copper product rough embryo is peeled out.