Exterior wall decorative panel is a new type of integrated material for building exterior wall decoration and insulation developed in recent years, which is composed of polyester baking paint or fluorocarbon paint, carved aluminum zinc alloy steel plate, polyurethane insulation layer and glass fiber cloth; It is mainly used for exterior wall decoration and energy-saving reconstruction of gymnasiums, libraries, school and hospital office buildings, villas and other buildings; The main functions are building decoration, heat preservation, energy conservation, heat insulation, sound insulation, waterproof and mildew proof. The metal surface decorative insulation board is a large external hanging wall board produced in industrialization. It has good durability and low maintenance cost due to dry installation construction. It integrates the external wall insulation and decoration functions, conforms to the development direction of building energy conservation "modularization" technology, and is an advanced technology vigorously promoted in the field of external temperature protection technology of building walls in China.

Most of the jades mentioned in daily life refer to nephrite, and there are many kinds of nephrite products. Generally, they refer to white sheepskin jade, white jade, topaz, purple jade, black jade, jasper, sapphire, ruby and northeast Xiuyu produced in Xinjiang. cost performance EPS exterior wall In the jade carving, the white jade with sheepskin is fine in texture and strong in luster, as white as sheepskin, which can be called "the king of nephrite" and "the crown of white jade". In addition, Nanyang jade, Lantian jade, Hotan jade, agate, crystal, coral, turquoise, lapis lazuli, etc., all belong to the category of nephrite. Later, due to the opening of the Silk Road, the jade produced in Hotan, Xinjiang, was unanimously recognized and began to play a leading role in the processing of royal, official and folk jade. EPS exterior wall Price Nephrite gradually evolved into a synonym for hotan jade.

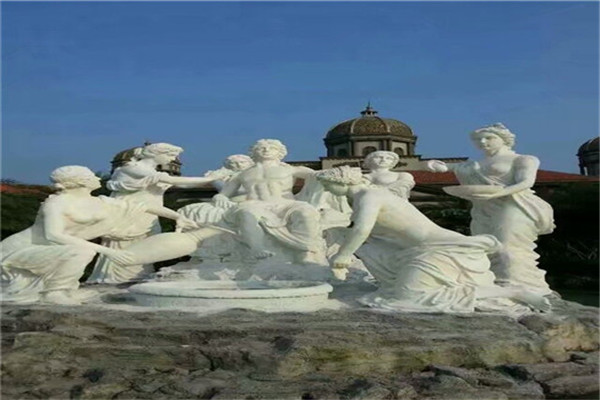

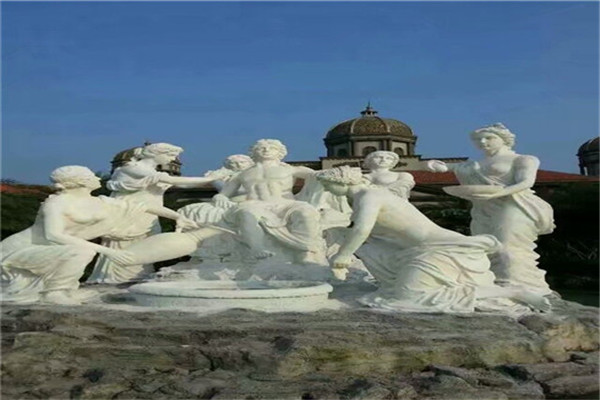

It is a three-dimensional plastic art to use certain material materials to produce works of art with solid image. Because the production methods are mainly sculpture and molding, it is called sculpture. According to the production process, sculpture can be divided into two categories: sculpture and sculpture. Subdivision is divided into carving, carving, molding, chiseling, carving, casting and other skills and techniques. According to genre, sculpture can be divided into memorial sculpture, urban garden sculpture, sculpture, tomb sculpture and exhibition sculpture. According to the style, sculptures can also be divided into head portrait, bust portrait, bust portrait, full body portrait, group portrait, etc. According to the technique and form of expression, sculpture can be divided into three categories: round sculpture, relief sculpture and openwork sculpture. Round sculpture, also known as "muddy sculpture", is a three-dimensional sculpture that is not attached to any background and can be viewed from all sides. The round sculpture is characterized by a solid image standing in space. When creating it, one must take into account its sense of volume and weight. When shaping the image, one must also take into account that people watch it from different angles. Relief, also known as "relief", is to carve a convex artistic image on the plane. According to the different degrees of surface relief, relief can be divided into high relief (high and low relief, deep relief) and low relief (low and low relief, shallow relief). The openwork is between the round sculpture and the relief sculpture. On the basis of the relief sculpture, it is made by hollowing out the background, but it does not leave the plane, just like a round sculpture attached to the plane background.

European style components, also known as GRC European style decorative components. GRC is the abbreviation of Glass Fiber Reinforced Cement. Hainan GRC component is a composite material invented and widely used abroad in the 1970s. It is a new composite material made of fast hardening Portland cement and alkali resistant glass fiber mixed with appropriate additives. It combines light weight, high strength, high toughness, water resistance, incombustibility, sound insulation, heat insulation, easy processing and other characteristics. Hainan EPS has a unique position in building materials. It is mainly used to make interior and exterior decoration components of European style buildings to meet the needs of European style decoration.

First of all, make the structural layer of the steel bar mountain mesh on the stone wall. According to the Hainan sculpture stone structure, the density of the steel bar is about 30 to 50 cm. Then, bind and weld the steel bar on the exposed steel bar head. Pay attention to the need to shape the approximate shape. After the steel bar is welded, tie a layer of steel wire mesh outside, and then start painting. The first painting is to make a base. For the second painting and shaping, it is necessary to make some rock texture, such as concave and convex, wrinkles, because the above steps must be grasped, and craftsmen must make the surface very artistic! Must have basic skills of modeling and stone molding. It is effective to spray stone like paint. Before large-area spraying, small samples were tested to show speckled particles in natural stone. Fill the gaps in the stone wall with earth and then plant them. Maybe fill some ceramic bottles and jars that are harmonious with the theme materials. There are still some water sources in the pottery to supplement its spatial diversity. There is also a new type of plastic stone, which is made of light materials such as environment-friendly building raw materials, fine resins, efficient reinforcing agents, pro aggregate, imported pigments, etc., by mixing, processing, and molding, and then steaming and curing at high temperature. Each product has different shapes and various combinations, which are no different from real stones in texture, color and texture.

Copper casting is an important part of Chinese traditional culture and art. Copper casting has a long history and mature technology. The process of casting copper is more complicated than that of forging copper, and the artistic creation has a good recovery. Therefore, it is suitable for becoming the material of fine works and is very popular with artists, especially figure sculpture. But it is easy to oxidize, so pay more attention to maintenance. Each cast copper artwork is made through 11 complex and rigorous processes, which include traces of traditional handicrafts, lines and modern technology of precision casting. Cast copper is put into the sintering furnace and sintered at 1000 ℃ - 1150 ℃ according to different metal materials. The copper liquid is immediately cast into the ceramic shell. After cooling, the outer ceramic shell is broken, and the copper product rough embryo is peeled out.